|

news releases news releases |

|

|

|

PDF Download(PDF Type, 23Kbyte) PDF Download(PDF Type, 23Kbyte) |

|

December 4, 2003 December 4, 2003 |

|

| Hitachi to Sell Inexpensive µ-Chip Inlets at Fraction of the Cost of Existing Inlets, Open the Way to Use in Various Applications |

|

|

|

|

|

Tokyo, December 4, 2003 --- Hitachi, Ltd. (NYSE:HIT / TSE:6501) today announced that its Mu-Solutions Venture Company would launch a µ-Chip PEM (Printing Etching Mask) Inlet on April 1, 2004 at a fraction of the cost of conventional RFID (*1) inlets. The inlets (*2), a combination of a µ-Chip and external antenna, will be priced at 10-19 yen (*3), approximately one-third to well below one-tenth (*4) the price of products now on the market. Making possible this lower price is a reduction in the majority of the costs involved in manufacturing inlets. For example, the number of stages in the antenna fabrication process has been reduced by employing the same technology used for full-color photograph printing in magazines. And inexpensive polyester film is used as the base film for the inlet-previously this was not possible because of problems with heat resistance. The solution was to use ultra-sound bonding technology, which connects the µ-Chip and antenna at a lower temperature. By substantially lowering the costs involved in manufacturing inlets, the price of RFID tags (*5), inlets embedded in paper, plastic and other materials, can be reduced, opening the way to a host of applications. For example, tags could be utilized to manage clothes inventories throughout the supply chain, for traceability of food products, and for other supply chain management (SCM) applications.

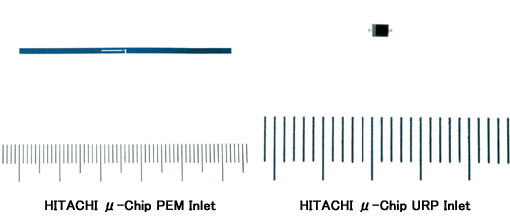

Coinciding with the release of the µ-Chip PEM Inlet, Hitachi will also release the µ-Chip URP(*6) Inlet, an ultra-small resin package that enables the surface mounting of a µ-Chip on a printed circuit board in its original form.

RFID tags, which transmit information stored on IC chips via electromagnetic waves, can be affixed to various objects, making them of use in a wide variety of applications. They are expected to find a home in a broad range of fields, extending from inventory management systems and distribution to security, electronic settlement of transactions, transportation, amusement, agriculture, production management and distribution management. The economic benefits of RFID tag solutions are estimated to reach ¥31 trillion in 2010 (*6). Already, the µ-Chip has been already selected for use in entrance tickets system for the 2005 World Exposition, Aichi, Japan that opens in March 2005, and field tests are being carried out with these tags to traceability agricultural produce. Applications of the Hitachi-developed µ-Chip are expanding all the time.

However, the price of conventional RFID inlets is prohibitively high, ranging from roughly 50 yen to several hundred yen per unit; there are only a limited number of fields able to justify this high cost, such as the process management of high-value products and logistics management. As a consequence, there have been demands for inlets priced at 10-19 yen; a level that would not cause price increases even in necessaries, to expedite the acceptance of RFID tags among manufacturers.

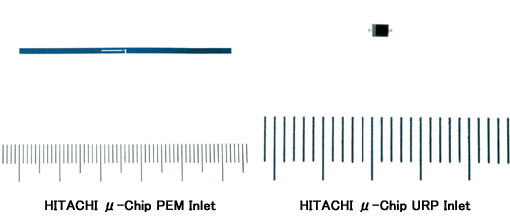

The µ-Chip is one of the world's smallest IC chips at 0.4mm x 0.4mm. The chip data is recorded in read-only memory (ROM) through the semiconductor production process, and therefore cannot be rewritten, thus guaranteeing its authenticity. To transmit the unique 128-bit ID number written in the chip to a reader, ordinarily an external antenna would be fused with a µ-Chip on a thin film, creating an inlet.

However, the external antenna fabrication process has until now involved many stages, raising the cost of manufacture. The process consists of four stages: (1) covering the surface with a protective film, (2) exposing photomask on the necessary parts, (3) removing unnecessary parts, and (4) etching. Furthermore, temperatures approaching 400 degrees centigrade have been required to create a highly reliable bond between the µ-Chip and external antenna. This required the use of highly heat resistant, but expensive polyimide film for the base film of the inlet.

The µ-Chip PEM Inlet overcomes these hurdles by utilizing new technology to shorten the external antenna fabrication process and allow the use of different materials for the inlet's base film. For the external antenna fabrication process, same as technology for printing color pages of magazines is employed to reduce the number of stages: (1) direct printing of the protective film in its required shape; and (2) etching. Furthermore, by employing ultra-sound bonding technology, the temperature required to connect the µ-Chip and the external antenna is lowered to below 100 degrees centigrade, without any loss in the reliability of the bond. This eliminates the necessity of materials with high heat resistance, and enable to use of inexpensive materials such as polyester film for the inlet's base film. As a result these innovations, the cost of this inlet is only around 10-19 yen, and reduced from one-third to one-tenth compared with conventional RFID inlets.

Through this innovation, the potential applications are extended. In the apparel industry, RFID tags could be embedded in product tags, replacing bar codes in stock management. In the retail trades, the amount of chemicals used on farm produce could be recorded making use of RFID tags and provided to consumers at retail stores as a way of guaranteeing the safety of produce.

Hitachi also plans to release the µ-Chip URP Inlet, an ultra-small resin package with an antenna already affixed to a printed circuit board that can be used to make RFID tags, alongside the µ-Chip PEM Inlet. These inlets are expected to be used to tag computers and other electronic appliances for lifecycle management. The use of an antenna already printed onto the circuit board for reading the µ-Chip's ID number removes the need for a base film, yielding an inlet costing a low 10-19 yen per unit. What's more, inlet mounting costs are expected to be lower.

Hitachi drives expansion in its RFID Solutions Business (*7) with the simultaneous launch of the µ-Chip PEM Inlet and µ-Chip URP Inlet.

| (*1) |

Radio Frequency Identification |

| (*2) |

An IC chip component used to make IC cards and RFID tags. It consists of an antenna or terminal for connecting an antenna and an IC chip. |

| (*3) |

The price per unit is 10-19 yen for orders of at least 1 million units. The price changes depending on the size of the order. |

| (*4) |

Source: Hitachi (As of November 2003) |

| (*5) |

Created when an inlet is embedded in paper, plastic or some other material. |

| (*6) |

The Ministry of Public Management, Home Affairs, Posts and Telecommunication's interim report on the high rate of use of electronic tags in a ubiquitous network era (August 2003) |

| (*7) |

A solutions business using µ-Chip and other RFID tags |

| About Hitachi, Ltd. |

| Hitachi, Ltd. (NYSE: HIT), headquartered in Tokyo, Japan, is a leading global electronics company, with approximately 340,000 employees worldwide. Fiscal 2002 (ended March 31, 2003) consolidated sales totaled 8,191.7 billion yen ($68.3 billion). The company offers a wide range of systems, products and services in market sectors, including information systems, electronic devices, power and industrial systems, consumer products, materials and financial services. For more information on Hitachi, please visit the company's Web site at http://www.hitachi.com. |

|

|

|

| Information contained in this news release is current as of the date of the press announcement, but may be subject to change without prior notice. |

|

|

|

PDF files are in Adobe's Portable Document Format. To view them you need Adobe® Reader® 6.0 by Adobe Systems Incorporated. If you are using Adobe Acrobat® 5.x software, you will need to download Asian font packs. |

|

|

|

|

|