In a first for Japanese industry, Omika Works was selected

by the World Economic Forum (WEF) as a Lighthouse—one

of the world's most-advanced factories

Omika Works is the first factory in Japan to be selected as a Lighthouse*, an initiative by the World Economic Forum (WEF) for designating the advanced factories around the world that are leading the way in the Fourth Industrial Revolution. Omika Works was selected in recognition of its optimization and upgrading across the entire value chain, achieved by combining technologies and expertise from OT, IT, and products as a part of its efforts to find solutions to various issues and to create new products.

* Lighthouse refers to acting as a "beacon" for industry. As of November 2020, 54 factories around the world have been selected.

The result of the amalgamation of the control panel operation of the former Hitachi Works and the power distribution panel operation of the former Kokubu Works, Omika Works was founded with the aim of becoming a world-class comprehensive system factory. Omika Works supports the quality and stable operation of social infrastructure by developing information control systems through an integrated system covering development, manufacturing, maintenance, and quality assurance.

In addition, Omika Works will continue to contribute to safe, comfortable, and fulfilled life by providing OT digital solutions and services for control system security and stable control system operation in the IoT age.

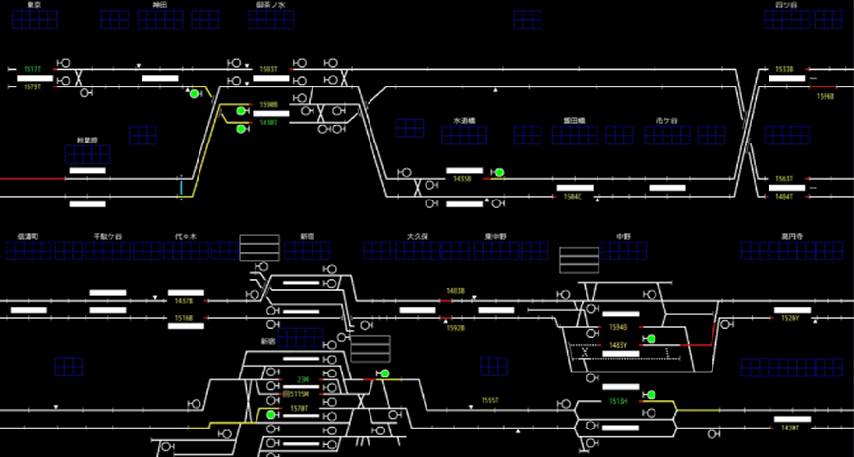

Social infrastructure, including electric power, railways, water supply and sewage, and industry, is indispensable to our daily lives. To enable the stable provision of social infrastructure services in these sectors, Omika Works provides information systems that use IT to perform the optimized operation of equipment and facilities. Through dialogue with our customers and partners, Omika Works handles total solutions for social infrastructure covering all aspects, from design and manufacturing to stable operation after delivery.

Information control systems support optimal facility operation by conveying signals from information and control systems to the propulsion machinery of the plant after converting them via control panel hardware. Serving as a comprehensive system factory, Omika Works designs, develops, and manufactures all the software and hardware for such information systems.

This is an initiative launched in 2018 by the WEF for selecting the world's most advanced factories that are leading the Fourth Industrial Revolution as a Lighthouse (i.e., a beacon). The advanced Lighthouse initiative is being shared globally to promote the digital transformation (DX) of industry

In the selection process, the factories of over 1,000 companies worldwide have been evaluated not only for improvements in productivity but also from the broad perspective of business sustainability, societal and environmental impact, and human resources development and work styles

The following achievements were highly evaluated as initiatives promoting the stable supply and operation of social infrastructure information control systems:

Optimization of the entire value chain—from hardware and software design, manufacturing, and development to system testing and post-delivery operation and maintenance—using digital solutions that leverage expertise in analyzing field data

Contribution to the finding of solutions for social issues by combining technology, experience, and expertise as a factory that combines and puts into practice OT and IT so as to realize collaborative production between people and digital

Hardware

Software

Shipping

Factory utility

Achieving mass customization

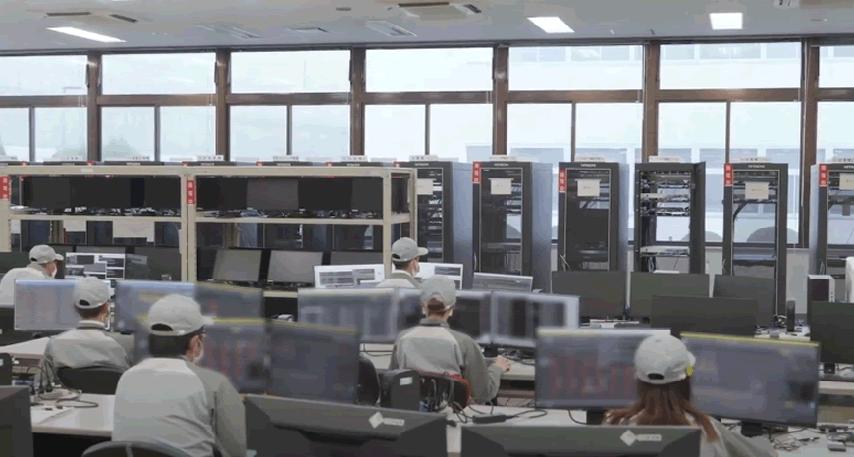

Focusing on the on-site 4M tenets of Humans, Machines, Materials, and Methods, Omika Works has established a high-efficiency production model based on the improvement cycle of data collection, data analysis, and measures.

The overall optimization of the production line, accomplished through production site visualization, modeling and automation of individualized tacit knowledge, and performance feedback plan design optimization enabled Omika Works to reduce the production lead time of core products by 50%.

Flexible response to market changes

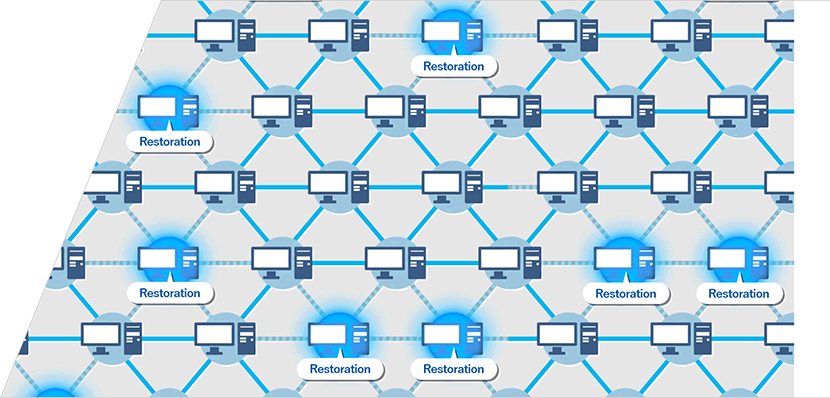

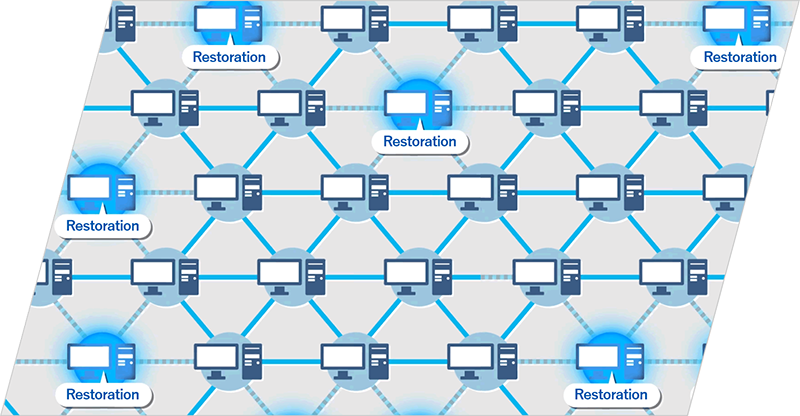

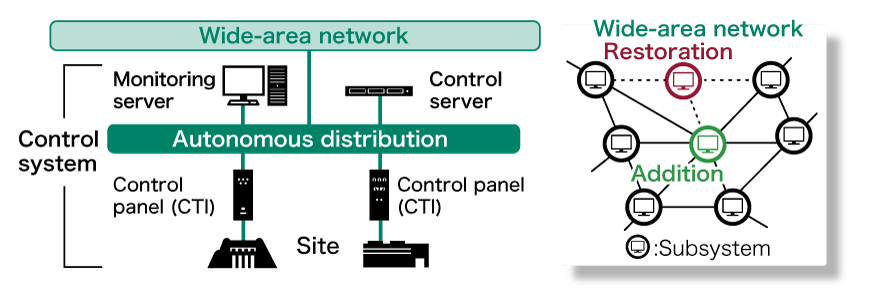

Omika Works developed and made into a framework a proprietary autonomous distributed system architecture that enables the safe expansion and maintenance of information systems while maintaining facility operations for social infrastructure that must operate continuously over the long term.

Having applied this system to about 4,000 critical infrastructure systems to date, Omika Works has manifested the development and operation of systems that flexibly respond to sudden changes in the market environment. In the field of railways, for example, it is possible to conduct coordinated control in which line sections are controlled independently, shielding them from system shutdowns on other line sections.

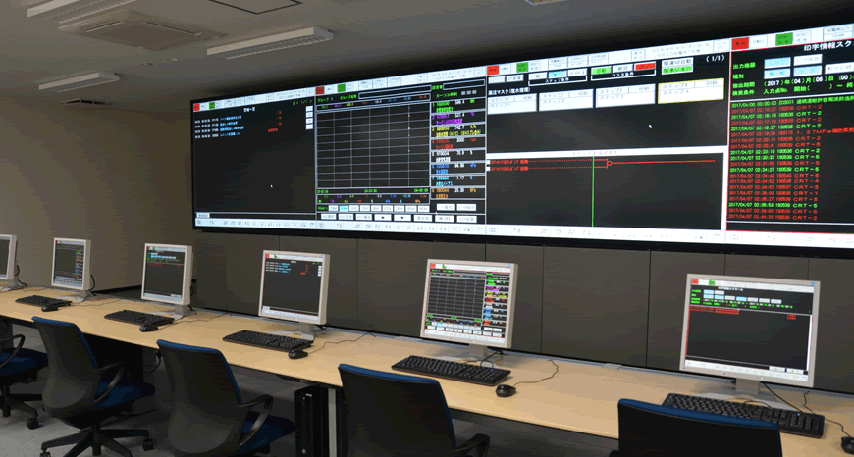

A simulator that simulates in cyberspace the environment of the actual project is used for system testing. System testing and modification/improvement rehearsals that cannot be carried at the customer's actual operational environment are comprehensively conducted at the factory, enabling Omika Works to provide highly reliable and high-quality systems.

Supporting advanced operations

In preparation for new cyber-attacks that can become threats in the IoT age, Omika Works will conduct practical training at a defense training and verification facility equipped with customer system environment simulation. This training will strengthen human resources development and organizational management by providing a place to learn operational technologies and such tasks as incident-level reporting and the reporting of information appropriate for making judgements as the managerial level.

Omika Works also assists in the operation and maintenance of customer systems by using advanced services that combine long-established OT and IT expertise.

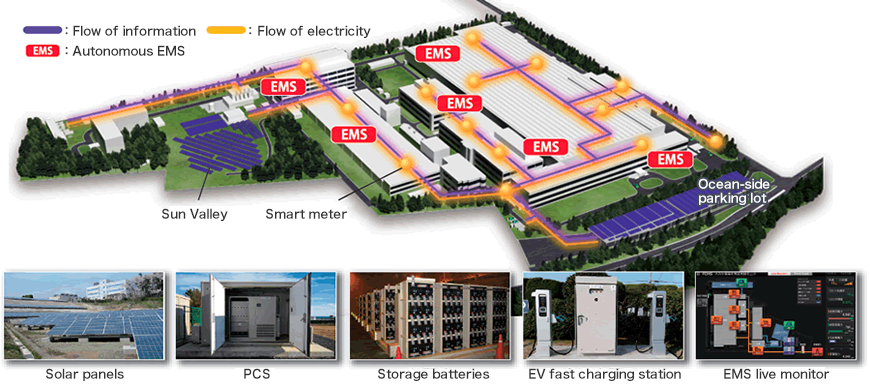

Omika Works has configured an energy-saving and disaster-resistant factory energy management system (EMS) comprising solar power generation, storage batteries, smart meters, and monitoring control systems, as a feature that delivers robust business continuity.

Peak load shifting through the linking of the EMS with the production plan and strengthening of BCP support through the autonomous operation of solar power and storage batteries combine to make Omika Works a smart eco-factory.

News Releases (Jan. 10, 2020)