Quality and Product Safety Management

- Approach to Quality Assurance Activities

- Framework for Quality Assurance

- Quality Assurance Activities

- International Standards Certification for Our Quality Management System

- External Audits Concerning Product Quality Assurance

- Quality and Reliability Education

- Response to Product Safety Incidents

Approach to Quality Assurance Activities

Approach & Policy

Hitachi was founded on the founding spirits of Harmony, Sincerity, and Pioneering Spirit. We ensure product quality and safety by adhering to these principles, along with the basics and ethics, and by putting right and wrong before profit and loss. We engage in quality assurance activities through our unique practice of OCHIBO-HIROI, which means gleaning in English and involves analyzing and learning from failure to further develop our technologies.

As stipulated in the Hitachi Group Code of Ethics and Business Conduct, we aim to provide products and services that meet the needs and requirements of our customers, complying with relevant laws and standards and ensuring quality and safety by setting additional standards of our own where necessary. We define our basic principles for quality assurance in Quality Assurance Standards, and we communicate these principles to ensure employee awareness.

Framework for Quality Assurance

Structure

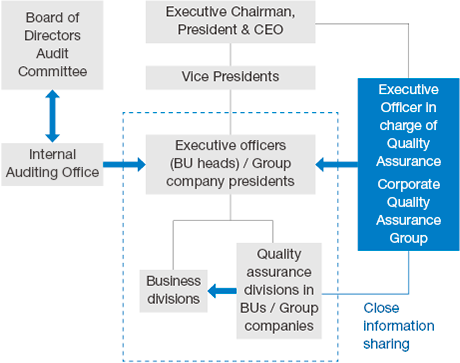

To ensure full control over quality governance, Hitachi establishes quality assurance divisions within business divisions to act independently from product design divisions and manufacturing divisions, creating a framework for activity in which the safety and trust of customers are the top priorities. To strengthen this structure further, we made quality assurance divisions independent from business divisions. We also strengthened the reporting line to the Corporate Quality Assurance Group at the headquarters, creating a system for close information sharing. Furthermore, by giving greater authority to the Corporate Quality Assurance Group we strengthened our quality governance.

When a product incident occurs in the Hitachi Group, the quality assurance division in the Business Unit (BU) or Group company with relevant oversight reports the incident to the Corporate Quality Assurance Group. Weekly reports are provided to management executives, including the Executive Chairman, and the President & CEO at Hitachi, Ltd. In the event of a serious incident, the quality assurance division in the BU or Group company reports the incident to management executives, including the Executive Chairman, and the President & CEO at Hitachi, Ltd., as promptly as possible. We review these response procedures every six months and make improvements as necessary.

Quality Assurance Structure

Global Quality Assurance Framework

Hitachi strengthens our global quality assurance framework as a high-priority initiative. Specifically, we encourage awareness of Hitachi’s basic principles of quality assurance globally, receiving incident reports from Group companies outside Japan. As in Japan, we are establishing international quality assurance reporting lines that are independent of the business divisions, as well as practicing OCHIBO-HIROI.

Quality Assurance Activities

Activities

Materiality

Hitachi strengthens organization and management, technology, and human capital aspects of our quality assurance activities in every process—from planning and development to design, manufacturing, testing, delivery, and maintenance. We engage in incident prevention activities that go beyond incident recurrence prevention, based on our approach that prevention is the essence of quality assurance.

Quality Enhancement Activities Related to Service, Software, and Security

To strengthen quality in software and services, areas that continue to grow in scale, we have established a Service and Software Quality Enhancement Division and share quality improvement activities and current challenges. At the same time, we ensure the software development capabilities and expertise in improving reliability owned in solutions divisions are incorporated in product divisions, ensuring higher levels of reliability in increasingly sophisticated and complex software. Furthermore, we are improving and incorporating secure development and maintenance processes for our products and services to respond to the increasing security risks arising from network connectivity and openness.

Technical Law Compliance Activities

Hitachi promotes internal awareness of product regulations, revised statutes, and enforcement dates in each country and region. We also work to clarify product-specific laws (with our product-specific laws map), pursue regulatory compliance, and implement continuous process improvements under our product compliance management system.

Pursued thorough Safety Design and Safety Monitoring for Products and Services

When developing products and services, Hitachi makes the safety of customer lives, health, and property the top priority in product design. We strive to ensure safety at every step, from development and production to sales and maintenance. We strive to ensure safety through risk reduction according to the following order of priority: design (fundamental safety design), protective measures (safeguards), and usage information such as user instruction manuals. Also, we conduct risk assessments from a wide perspective in collaboration with related BUs and research laboratories.

International Standards Certification for Our Quality Management System

Activities

Hitachi’s quality management system has acquired certification from external certifying organizations. We are committed to effectively applying the findings of third-party evaluations to our improvement activities as well.

We have also obtained quality management system certification for each of our product categories worldwide. The chart below shows a representative sample.

Management System Certification

| Area | Name of Standard | Number of Certified Sites |

|---|---|---|

| Overall Quality | ISO 9001 | 1,015 sites |

| Railway Business | ISO/TS 22163 | 13 sites |

| Medical Devices | ISO 13485 | 20 sites |

Note :Survey results as of the end of June 2024

External Audits Concerning Product Quality Assurance

Activities

Hitachi commissions regular external audits of product safety for certified products and other products.

Relevant logos indicate products that have received certification. We also commission regular external audits following certification to confirm ongoing quality standards.

S-Mark: Indicates third-party certification for electronics based on a certification system administered by the Steering Council of Safety Certification for Electrical and Electronic Appliances and Parts of Japan (SCEA). (Frequency of external audits: 1 time/year, Subject to audits: Product and factory quality control)

UL Mark: Indicates compliance with safety standards established by UL Solutions, a safety certification company. (Frequency of external audits: 4 times/year, Subject to audits: Products)

Quality and Reliability Education

Activities

Hitachi regularly provides various forms of education and training related to quality and reliability, including the safety of products and services, depending on the target employees. In addition to implementing e-learning courses on Hitachi’s philosophy regarding quality, available at any time for all employees, we also feature quality assurance as a topic for position specific and executive-oriented training, as well as new employee education. We also hold various basic and technical reliability-related for specialists every year. Each BU also conducts specialized technical courses regarding manufacturing, quality assurance, and maintenance.

Response to Product Safety Incidents

Activities

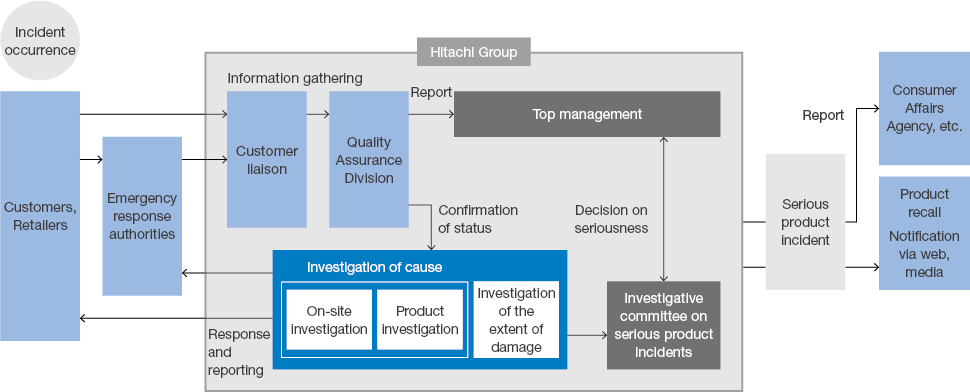

In the event of an incident, the division responsible acts swiftly to resolve the problem. We not only investigate the technical causes, but also thoroughly discuss the process, framework, and motivating factors leading up to the occurrence, along with ways to prevent recurrence, to ensure product safety.

In the case of a severe incident, we provide prompt status reports to top management, issue reports to government agencies in line with legal requirements, and provide relevant information disclosure to customers on our website and through other communication channels. At the same time, we have a framework in place to ensure that fast and appropriate action is implemented at all companies across the group.

If we determine that retroactive action is necessary, we notify customers via newspaper advertising and websites to carry out the necessary repair or replacement program.

Response Procedure for Product Incidents