Factors such as global economic instability, climate change, industrial field transformation, and changes

in the working environment are resulting in an uncertain business environment.

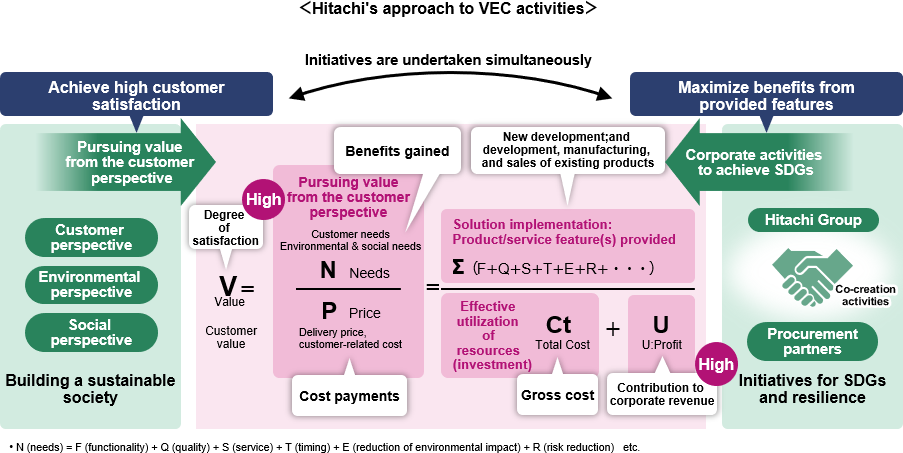

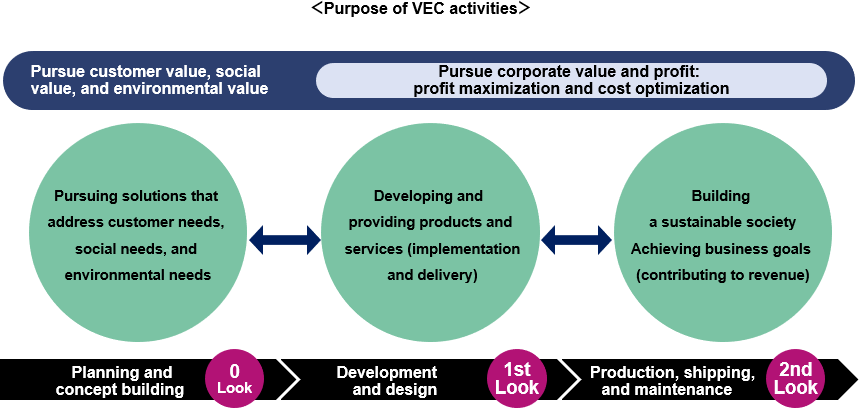

In such an environment, Hitachi will continuously create customer value (Value for Customers), environmental value (Value for Environment), and social value (Value for Society)

through VEC activities. We believe that it is important to continue our business with products and services that address customer needs.

The Hitachi Group is engaged in VEC activities to create and increase value, with the focus on the following two points.

Starting with the introduction of VA (value analysis) in Hitachi's Materials Division in 1960, we have expanded the activities to Hitachi Group companies and developed VEC (Value Engineering for Customers) with a stronger customer orientation. A feature of VEC activities is that they are based on TFP (Task Force Project) activities. TFP is a method for creating a cross-functional organization and promoting project activities that continue for a certain period.

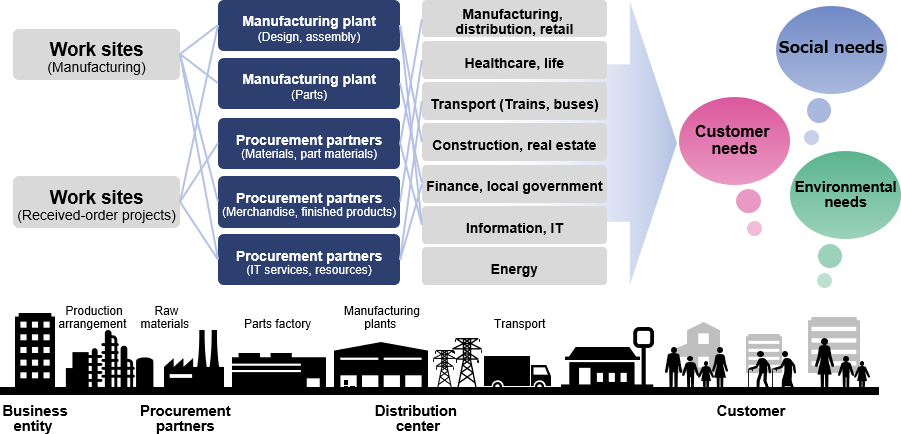

VEC applies to every activity in the entire value chain and covers every activity related to the improvement of customer value from product planning to production, distribution, and maintenance. It includes cost planning, sales, development design, purchasing, manufacturing (machining, assembly, packaging, outsourced work, etc.), logistics, and maintenance. In addition to the manufacturing industry, we are expanding VEC into various industries, including mass production and received-order projects. Recently, VEC has been introduced in sales activities, document preparation and administrative procedures, as well as in the distribution and construction industries.

QCD (quality and functionality, cost, delivery times and amounts) of procured products are major factors in determining development and manufacturing costs. In addition to purchasing QCD, Hitachi procurement divisions also procure technologies, skills, know-how, information, development capabilities, time, etc., which are the source of value creation. At the planning and development design stages, Hitachi has established a system that procurement partners and related departments including the engineering department participate in, and we are working to expand the benefits of value creation by engaging in VEC activities for purchased and procured products.

Hitachi is developing a variety of businesses and business models, including digital solutions, IT products, railway systems, building systems, lifestyles and ecosystems, healthcare, industrial and distribution solutions, and water and environmental solutions. VEC can be applied to all industries that provide products and services to customers.

Hitachi believes that it is important to create value with procurement partners involved in the entire value chain, including the parts related to materials and components, products and finished products, and IT services and resources. For this reason, we will jointly develop elemental technologies from the planning and conceptual stage (sales activities, product planning, etc.) in the development of business processes and products and services, and undertake initiatives to adopt advanced technologies. Focusing on reducing environmental impact, recycling materials, and reducing the amount of materials used, we will undertake initiatives in joint VEC activities together with our procurement partners.