Concept Proven to Successfully Extract Features Suitable for Machine Learning from In-mold Sensors Injecting Recycled Materials to Automatically Stabilize Molded Parts Quality When Using Recycled Materials with Varying Material Properties

May 10, 2022

Hitachi, Ltd. has developed technology using AI to automatically optimize plastic molding conditions to expand the use of recycled plastic materials. This technology has been shown to stabilize the quality of molded parts by controlling the molding process using in-mold sensor data, even with varying recycled material properties between production lots. Hitachi aims to help realize a circular economy via the reduction of waste plastics by applying this technology to a wide range of recycled materials.

The production of greenhouse gases, the depletion of oil reserves, environmental pollution, and other problems resulting from mass consumption of plastics have been recognized as important planetary boundaries*1 issues. In light of these problems, 3Rs*2 is one approach being promoted worldwide to address the issue of plastic waste. The properties of recycled materials made from a variety of waste plastics tend to fluctuate lot-to-lot due to various contaminants. Operators have struggled to control quality when molding new plastics from recycled materials with inconsistent material properties. This has been an obstacle to broadening the use of recycled materials because manufacturers have tended to only use recycled materials with consistent material properties as a result. To use recycled materials with material properties that fluctuate between each lot, a skilled operator has had to finely adjust the conditions of the molding process manually according to the recycled materials properties when molding plastics, which made practical use difficult.

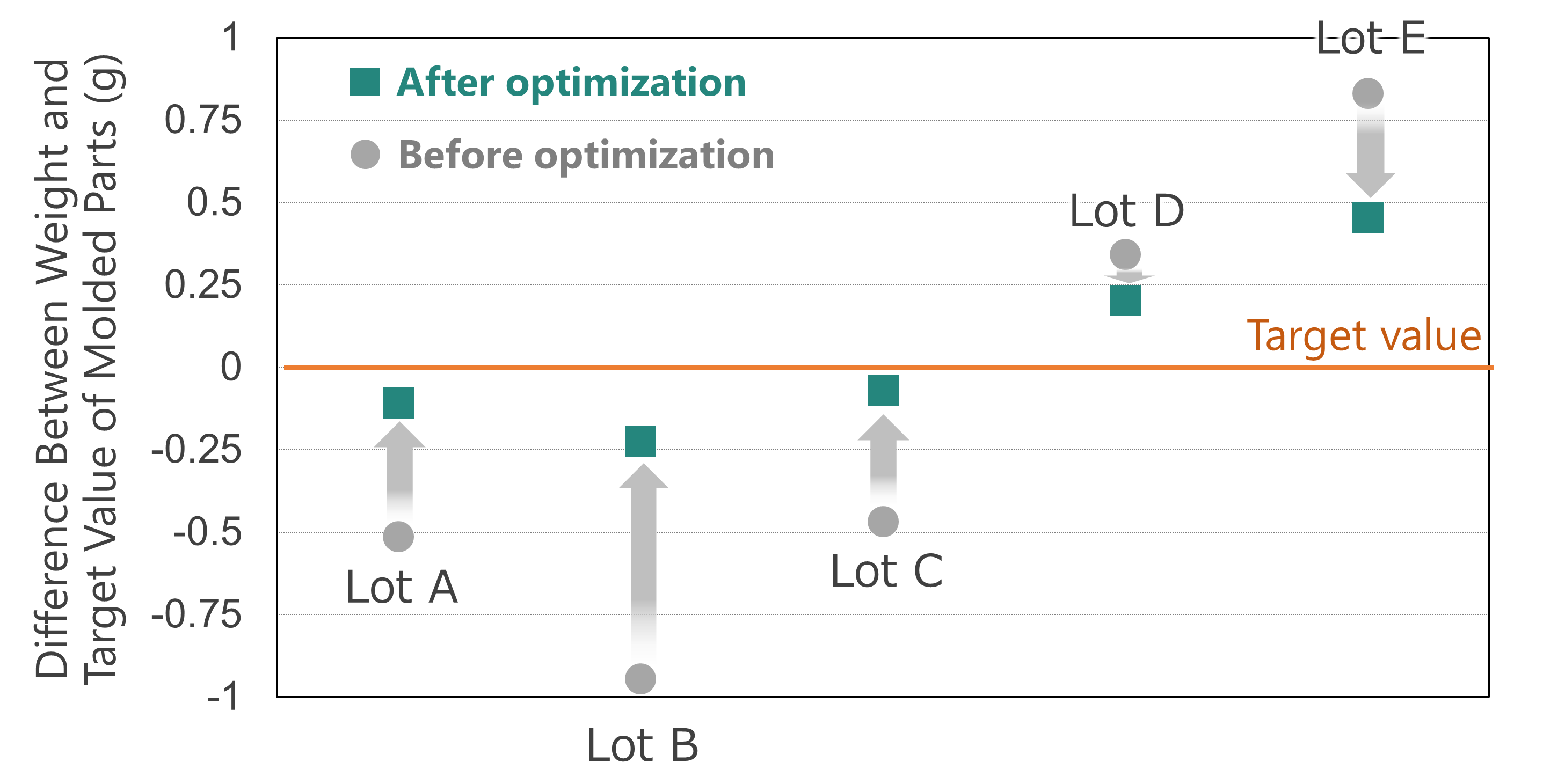

Hitachi has succeeded in using in-mold sensor data when injecting recycled materials to extract the varying properties between recycled material lots as features*3 suitable for machine learning. The technology it has developed has also proven successful in automatically stabilizing the quality of plastic molded parts made from recycled materials using this AI without relying on a skilled operator for the first time. Specifically, when this AI was applied to 5 lots of recycled materials whose properties fluctuate lot-to-lot, the weight of molded parts under the optimized process conditions approached the target value in all lots (Fig. 1).

Hitachi plans to present some of these results at the 37th International Conference of the Polymer Processing Society held from April 11 to April 15, 2022.

Fig. 1. Results Demonstrating a Reduction in Quality (Weight) Variations Between Molded Parts by Automatically Optimizing the Conditions for Molding Processes of Each Recycled Material Lot

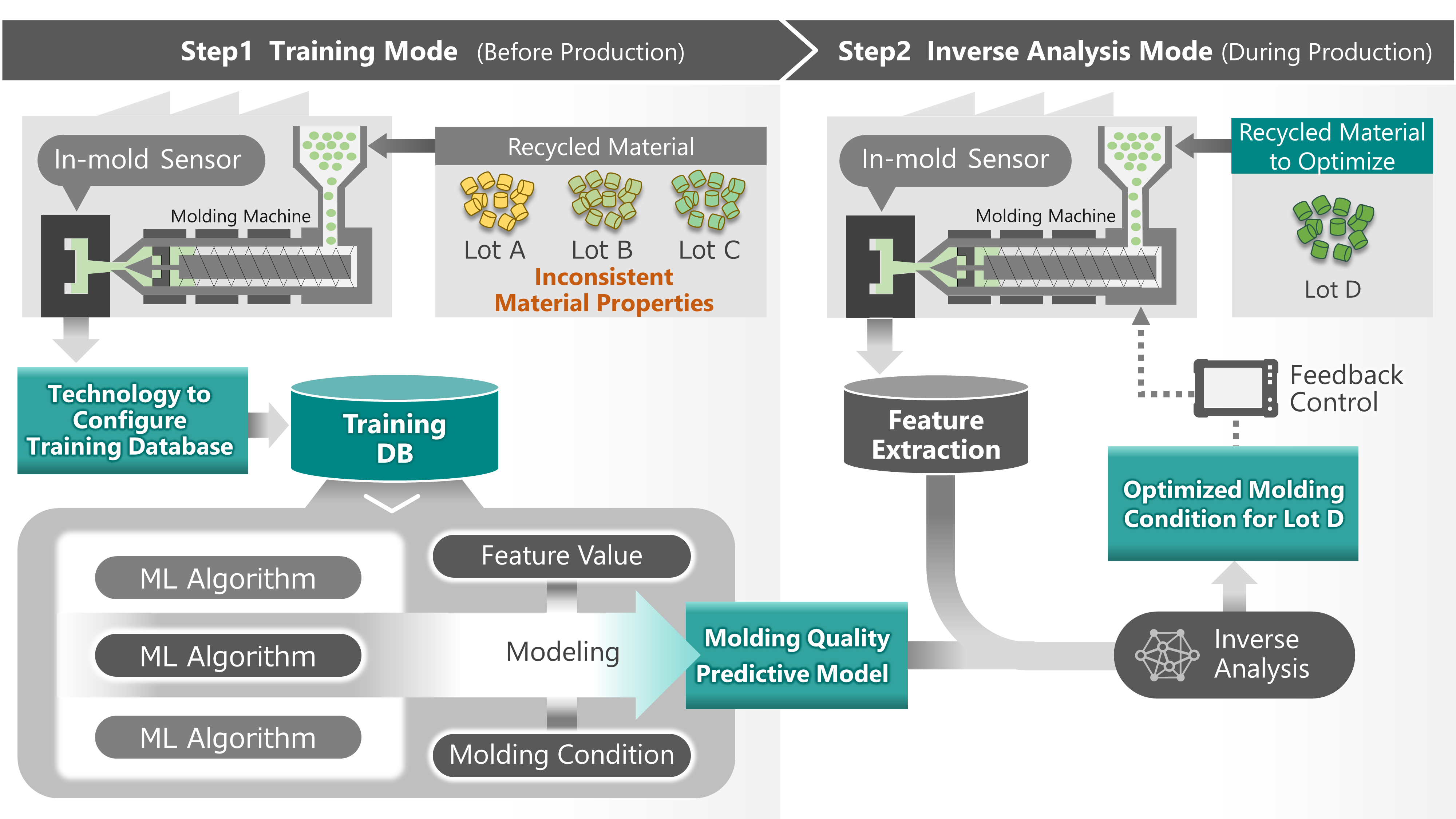

This AI technology for injection molding process*4 consists of a training mode (before production) and an inverse analysis mode (during production) (Fig. 2). The training mode generates a highly accurate model estimating the quality of the molded parts from the recycled material features and molding conditions using the training database described later by automatically selecting a best algorithm from multiple machine learning algorithm. The inverse analysis mode obtains the optimized molding conditions from the predictive quality model of the modeled parts and features of the recycled material to be optimized by using an inverse analysis of models*5.

Fig. 2. Automated Optimization AI for Plastic Molding Processes

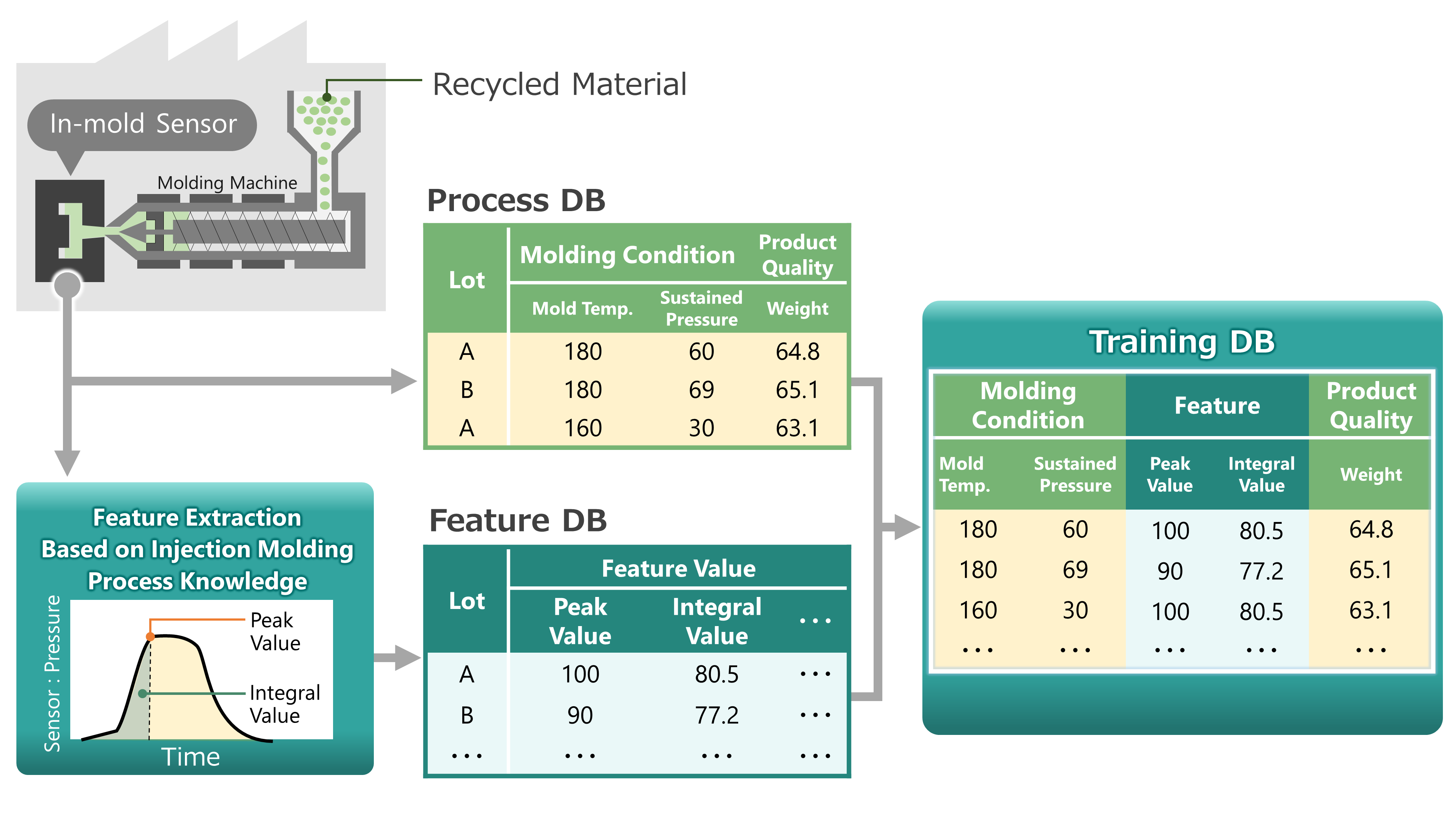

It is essential to configure an appropriate training database in order to generate a highly accurate predictive model of the molded parts quality, which in turn requires a high-level of knowledge about how to control the molding process. Hitachi developed this technology to configure the training database in a way that correlates the relationship between the conditions for the plastic molding process, the quality of the molded parts (weight), and the recycled material properties.

The training database consists of a process database linked to the feature database (Fig. 3). Firstly, the process database uses design for experiments*6 based on expert knowledge of molding processes to molded parts while changing molding conditions and the recycled material lots, and then inputs data linking the molding conditions and molded parts quality. Next, the feature database extracts and inputs the features associated with the recycled material properties according to pressure, temperature, and other various in-mold sensor data while using the same molding conditions for each recycled material lot.

Hitachi succeeded in extracting features from the sensor data to optimize settings for lot-to-lot variations from the sensor data for the first time by applying the knowledge it had accumulated in injection molding through research and development, including technology for plastic molding error correction*7.

Fig. 3. Techhology to Configure the Training Database to Generate the Molding Quality Predictice Model.

For more information, use the enquiry form below to contact the Research & Development Group, Hitachi, Ltd. Please make sure to include the title of the article.